About Us

ENERGENT is a specialist engineering solutions provider delivering precision-engineered industrial process management systems for mining and heavy industrial environments. Our expertise lies in performance-critical infrastructure, where operational safety, energy efficiency, and full compliance with stringent environmental and occupational standards are non-negotiable.

Leveraging deep knowledge in rotating machinery, advanced aerodynamics, and reliability engineering, ENERGENT approaches every project with a combination of high-fidelity modelling, predictive diagnostics, and lifecycle-optimised design principles. Our systems are built for high-demand, continuous-operation environments—often surpassing industry benchmarks for efficiency, reliability, and service life.

By integrating cutting-edge monitoring technologies, structurally robust mechanical design, and rigorous performance verification protocols, we deliver solutions proven to withstand the harshest operational and environmental conditions. This capability has made ENERGENT a trusted partner for clients seeking not only long-term stability but also measurable, sustained operational gains.

Industrial Process Management Systems

Our Duty

At ENERGENT, we deliver performance-focused engineering interventions that safeguard operational continuity, enhance safety margins, and extend asset life cycles in high-demand industrial and mining settings.

Rather than generic offerings, our work is driven by bespoke performance models and rigorous engineering governance, ensuring that every solution is precision-matched to the client’s operational profile.

Our portfolio spans reliability-driven asset interventions, high-integrity rotating equipment optimisation, and integrated monitoring platforms that give clients complete confidence in operational resilience.

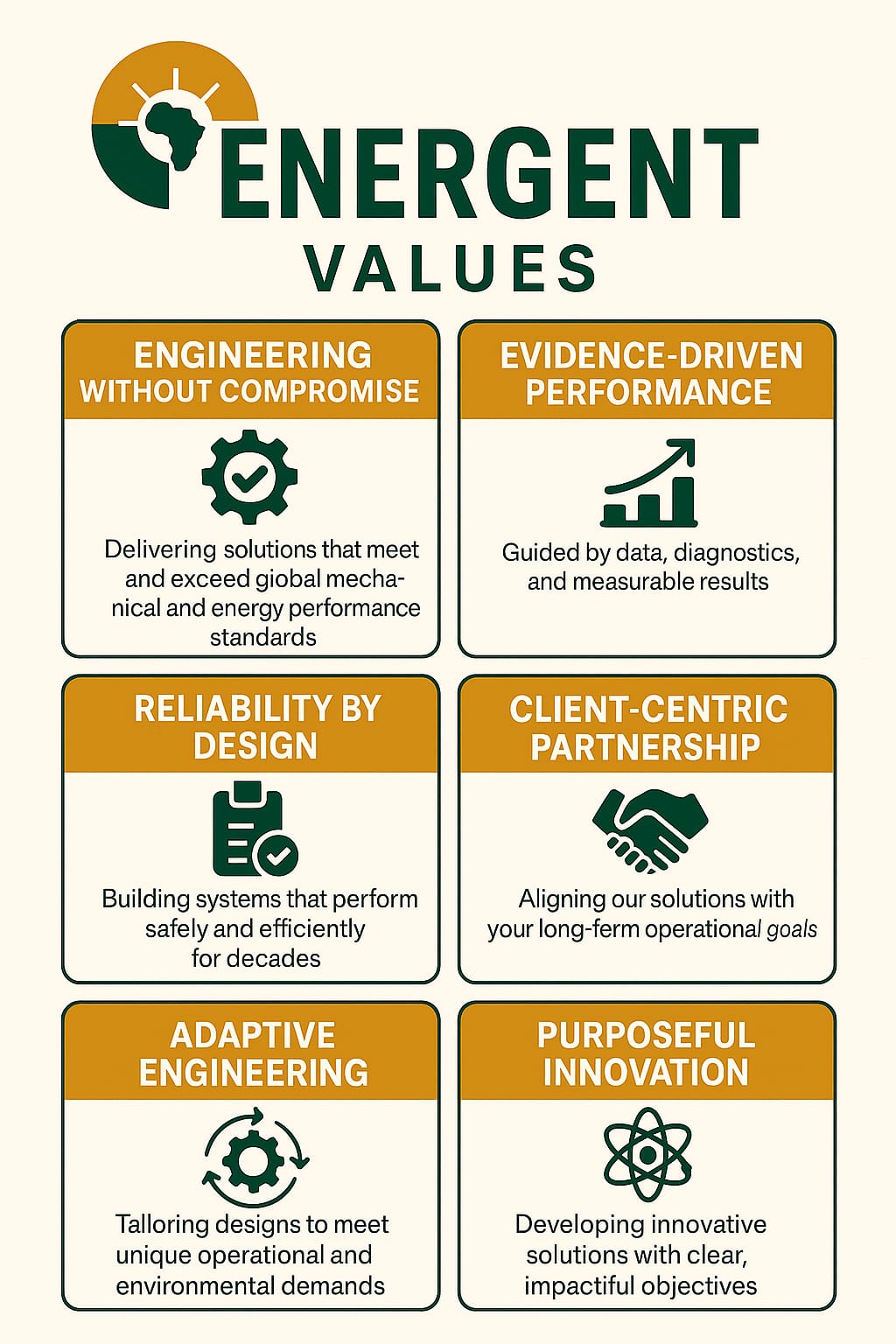

Why Clients Choose ENERGENT?

Core Competence Areas

(Presented without giving away process specifics)

Critical Infrastructure Systems — Engineering precision solutions that ensure safe, compliant, and optimised operating environments.

Rotating Equipment Performance Assurance — From core design principles to operational tuning for energy efficiency and load optimisation.

Operational Continuity Engineering — System-level interventions that ensure uptime in environments where downtime is not an option.

Advanced Monitoring & Control — Intelligent integration of real-time performance tracking with predictive operational insights.

Our Mission